Our process

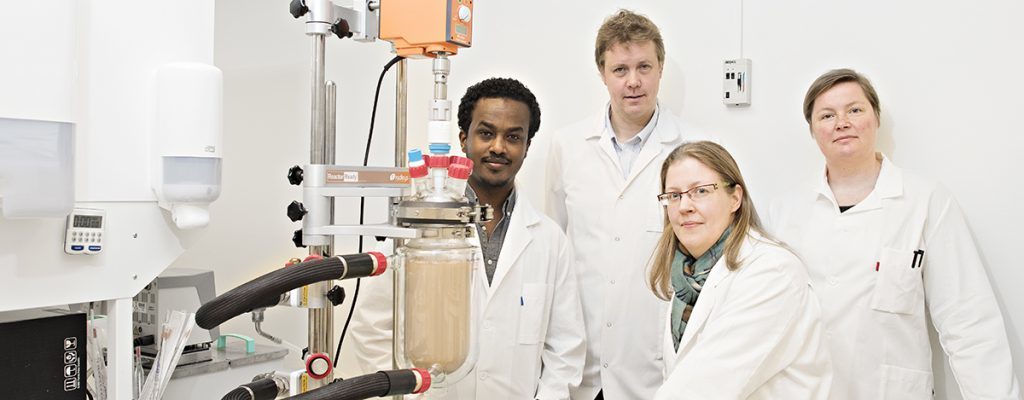

Photo: Sune Eriksen

Biorefinery for efficient and sustainable use of resources

It is important to use the world's resources efficiently and sustainably, and minimize food waste. We believe in using the whole animal, all parts, and we use biorefinery as a method to achieve this. In this way, offcuts from chicken and turkey can be made into valuable ingredients.

Enzymatic hydrolysis - using nature's toolbox to produce quality ingredients

Enzymatic hydrolysis is the process that we use to gently and naturally refine poultry offcuts. The process uses enzymes, which are natural "tools" that can split protein-rich raw materials into smaller proteins and peptides. After separation and drying, we end up with three products: hydrolyzed proteins and peptides, oil, and minerals.

Photo: Sune Eriksen

What is enzymatic hydrolysis?

Bioco uses continuous enzymatic hydrolysis to refine chicken and turkey raw materials and create hydrolyzed proteins and peptides. What does that mean, and how does that work?

Bioco's process: continuous enzymatic hydrolysis

Bioco has implemented continuous enzymatic hydrolysis for the hydrolysis of poultry raw materials. This provides benefits for product quality compared to batch enzymatic hydrolysis, which is a great advantage for Bioco's customers.

What is enzymatic hydrolysis?

Bioco uses continuous enzymatic hydrolysis to refine chicken and turkey raw materials and create hydrolyzed proteins and peptides. What does that mean, and how does that work?